Sugarcane paper bagasse lid for bagasse bowls

description1

description2

Specification

Size (mm) |

167.8*167.8*15.5 |

Weight (g) |

10 |

Carton Size (cm) |

35*34.5*35 |

Packing (pcs) |

50*8 |

Raw Material |

Sugarcane Bagasse Pulp |

Product Service |

Free sample with postage at your own expense |

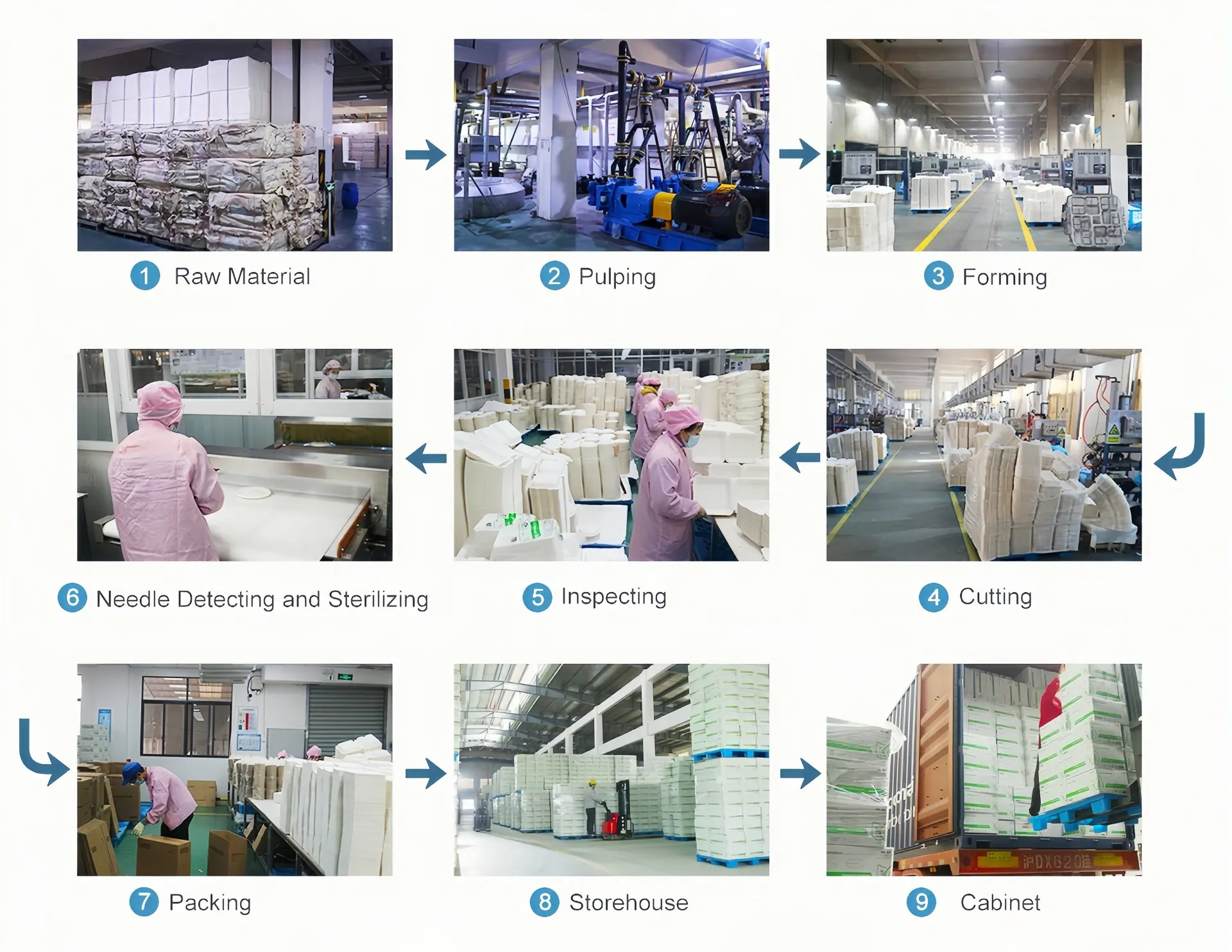

Producing bagasse dinnerware involves several steps, from sourcing the raw material to the final product. Bagasse is the fibrous residue left after the extraction of juice from sugarcane, making it a sustainable and eco-friendly option for dinnerware. Here’s a detailed overview of the process:

1. Sourcing Raw Material

Sugarcane Harvesting: Bagasse is a byproduct of sugarcane processing. The sugarcane is harvested and sent to sugar mills.

Juice Extraction: At the mill, the sugarcane is crushed to extract the juice, leaving behind the fibrous material known as bagasse.

2. Bagasse Collection and Preparation

● Collection: The bagasse is collected from the sugar mills after the juice extraction process.

● Drying: The collected bagasse is dried to reduce moisture content, which is essential for the subsequent processing steps.

3. Pulping

● Pulping Process: The dried bagasse is then pulped, which involves breaking down the fibers into a slurry. This can be done using mechanical or chemical methods.

● Cleaning: The pulp is cleaned to remove any impurities, such as dirt or residual sugar.

4. Molding

● Forming the dinnerware: The clean pulp is then formed into the desired shapes using molds. This can be done through various methods, including:

● Compression Molding: The pulp is placed in molds and subjected to heat and pressure to form the dinnerware.

● Injection Molding: The pulp is injected into molds to create specific shapes.

5. Drying

● Drying the Molded Products: After molding, the dinnerware is dried to remove any remaining moisture. This can be done using hot air dryers or in an oven.

6. Finishing

● Trimming and Quality Control: The dried products are trimmed to remove any excess material and checked for quality. This includes inspecting for defects and ensuring that the products meet the required standards.

● Coating (Optional): Some manufacturers may apply a food-safe coating to enhance the durability and water resistance of the dinnerware.

7. Packaging

● Packaging: The finished bagasse dinnerware is packaged for distribution. Eco-friendly packaging materials are often used to maintain the sustainability aspect of the product.

8. Distribution

● Distribution: The packaged dinnerware is then distributed to retailers, restaurants, and consumers.

9. End-of-Life Considerations

● Biodegradability: Bagasse dinnerware is biodegradable and compostable, making it an environmentally friendly alternative to plastic and Styrofoam products. This aspect is often highlighted in marketing and consumer education.

Production Process