9*8 inch eco-friendly bagasse pulp clamshell

description1

description2

Specification

Size (mm) |

402.5*230*72.5 |

Weight (g) |

38 |

Carton Size (cm) |

42*33*24 |

Packing (pcs) |

100*2 |

Raw Material |

Sugarcane Bagasse Pulp |

Product Service |

Free sample with postage at your own expense |

Home Compostable

Our bagasse packaging with no added PFAS* is certified home compostable to Australian (AS5810) and European Standards (NF T51-800) and certified industrially compostable to Australian (AS4736) and European Standards (EN13432). This means it’ll biodegrade in 30-90 days in composting conditions, leaving behind no toxic residue and creating nutrient-rich compost.

Rapidly Renewable Resource

Since bagasse is made from sugarcane pulp, it can reduce the need to cut down trees and slow deforestation.

According to a report by the Union of Concerned Scientists, timber production has been identified as one of the four key contributors to deforestation. They state, “wood production has been shown to cause around 380,000 hectares of deforestation annually in key countries” .

“Why does deforestation matter? Forests—especially tropical forests—store enormous amounts of carbon. When forests are destroyed, that carbon is released to the atmosphere, accelerating global warming.Deforestation accounts for around 10% of total heat-trapping emissions—roughly the same as the yearly emissions from 600 million cars.”

Trees take a long time to grow to maturity before they can be harvested. And when harvesting them, acres of land are cleared making it a resource-intensive process. Sugarcane, on the other hand, can be harvested annually making it a rapidly renewable resource.

At CoPak, we combine our sugarcane pulp with other plant-based pulp to create ‘plant fibre.’ So while it’s not considered ‘tree free’, our bagasse products contain at least 70% reclaimed plant fibre and will still significantly reduce our reliance on trees and deforestation.

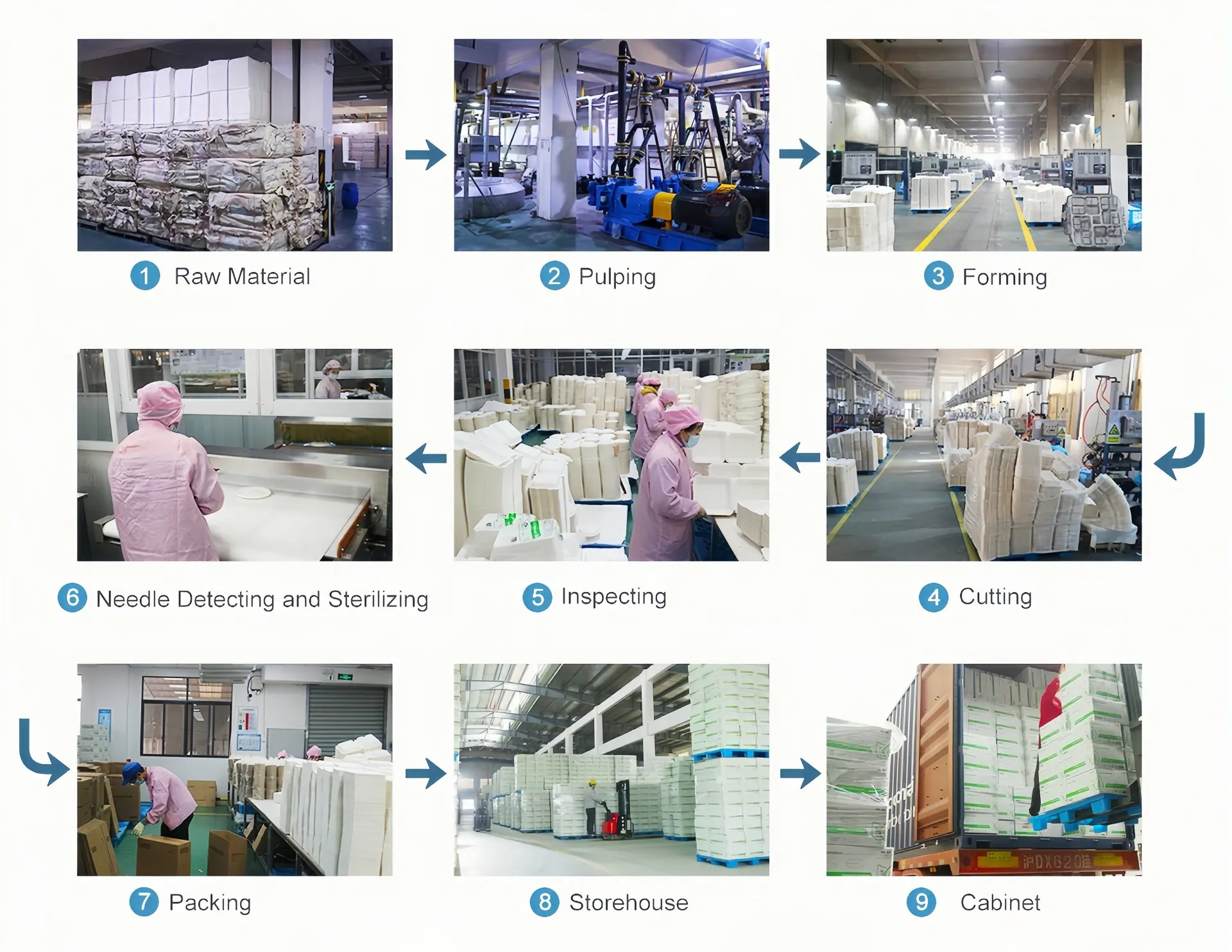

Production Process