9*8 inch 2 compartment bagasse pulp clamshell

description1

description2

Specification

Size (mm) |

402.5*230*72.5 |

Weight (g) |

38 |

Carton Size (cm) |

42*34*24 |

Packing (pcs) |

100*2 |

Raw Material |

Sugarcane Bagasse Pulp |

Product Service |

Free sample with postage at your own expense |

Bagasse is a fibrous material left behind after harvesting sugarcane. It has a multitude of uses, especially in the foodservice packaging industry as a sustainable alternative to conventional plastic. This article will dive into bagasse, how it’s made, the environmental benefits and how it fits into the circular economy.

Bagasse, otherwise known as sugarcane pulp, is a by-product of the sugarcane industry. It’s the fibrous substance that’s left behind after the juice of the sugarcane plant is harvested.

Up until recently, bagasse was often disposed of or left to rot. But today, it’s used as a renewable resource for the production of paper products and as a fuel for factories.

How Is Bagasse Made?

Bagasse can be used for multiple purposes, from biofuel to paper, with each product having its own production method. Let’s look at the specific method involved for the production of bagasse packaging products.

● After one year, the sugarcane plant is ready for harvest.

● The sugarcane plant is harvested for its liquid. Once this liquid is extracted, the leftover substance (bagasse) is kept wet and blended with water to form a pulp.

● Additives are mixed in with the pulp before being pressed into the shape of a packaging product by applying pressure and high temperatures.

● The end result is a sturdy, microwavable and compostable food packaging product made from plant-based, renewable resources.

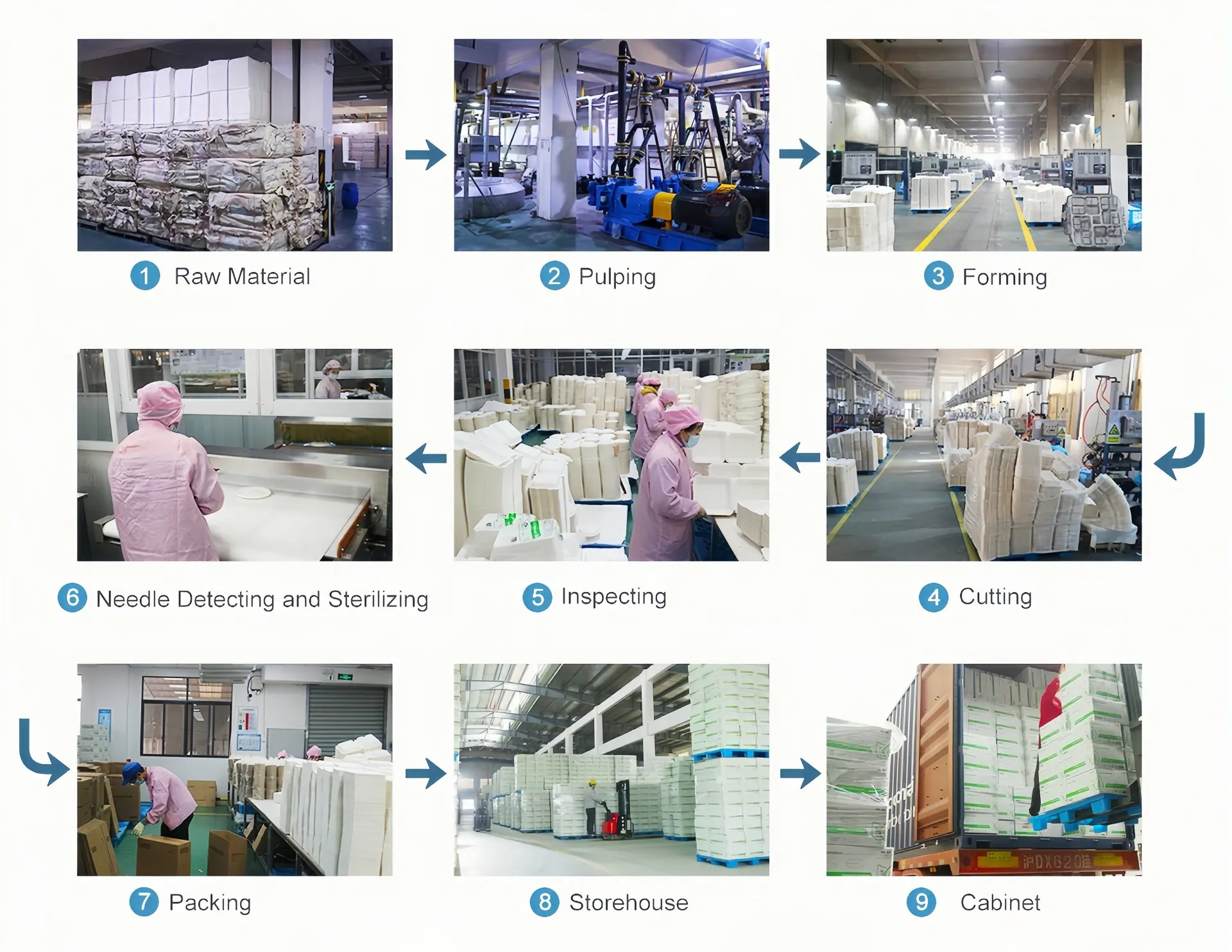

Production Process