12OZ eco friendly disposable cup with lid

description1

description2

Specification

Size (mm) |

Ø90*112 |

Weight (g) |

12.5 |

Carton Size (cm) |

47*39*47 |

Packing (pcs) |

50*25 |

Raw Material |

Sugarcane Bagasse Pulp |

Product Service |

Free sample with postage at your own expense |

Mostly, it’s just the plant from which the material is extracted.

Once processed, bagasse looks, feels and acts similar to paper. The main difference is that instead of pulping wood from trees, it’s sourced and formed from a waste product of sugar production.

This difference is significant when considering how sustainable bagasse versus paper is, as bagasse comes from a resource that renews reasonably quickly. It can take just six months for sugar cane to be grown to harvest, whereas trees and forests take considerably longer (between 7-10 years) and comes with issues associated with deforestation.

Moreover, 1.5 tonnes of sugar cane pulp produce 1 tonne of bagasse paper; however, it takes 5 tonnes of wood to produce 1 tonne of paper.

Why does bagasse make good food packaging and dinnerware material?

Bagasse is suitable for both hot and cold products, making it very useful for food packaging and dinnerware. Additionally, it can be put in the freezer and the microwave. It’s water-resistant and suitable for greasy foods and hot applications (up to 120℃).

What is the best end-of-life for bagasse?

Industrial composting.

Bagasse can be sent to an industrial composting facility alongside food waste to be composted under specific conditions.

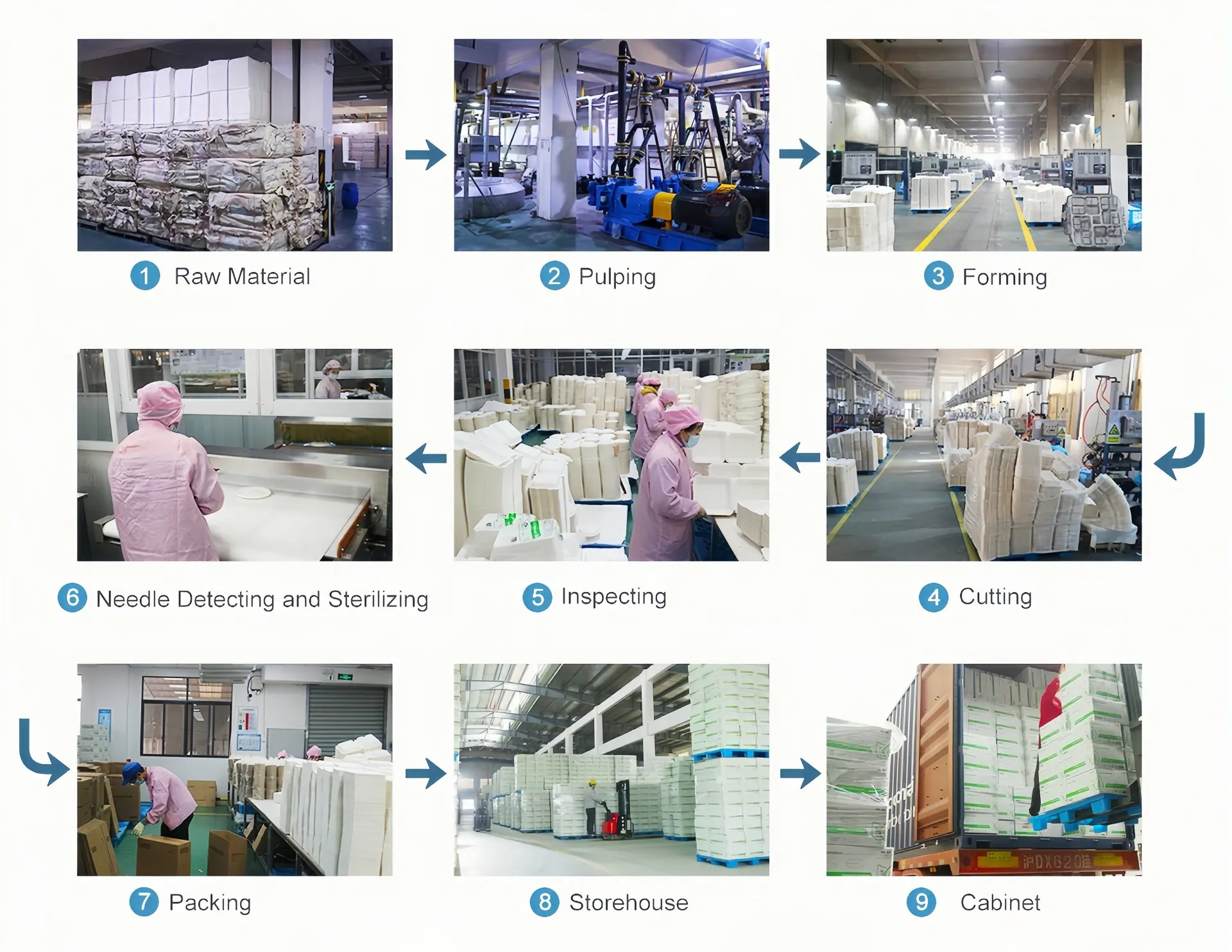

Production Process